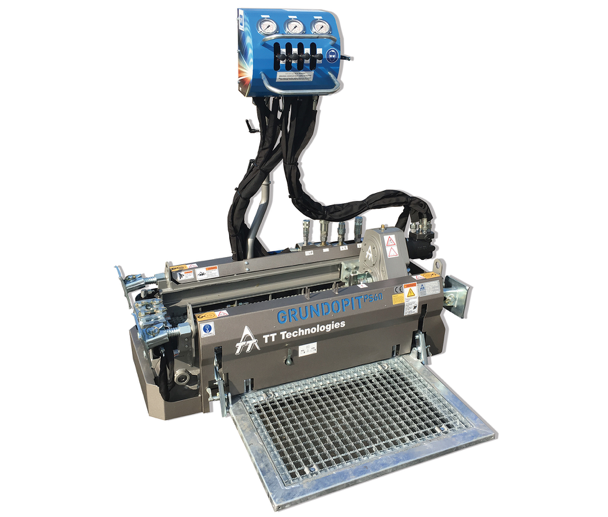

One risk of the direct pipe method is a prolonged mechanical breakdown in the midst of the drill. The following figure depicts a direct pipe installation passing beneath a river. The below figure illustrates how the drilling mechanism (far left) is attached to the pipeline. The returns from the drilling are delivered back to the surface via umbilicals inside the advancing pipeline. The direct pipe drilling head is attached to the end of the pipeline, such that as the drill head advances through the earth, the pipeline is pushed/pulled along behind it. With direct pipe installations, these two steps happen simultaneously. The Williams Companies, Inc., Subsurface Pipe Installation (2014).Īs described above, the HDD method creates the tunnel first and then, as a second step, the pipeline is pulled through it. Direct Pipe installations may be much shorter and shallower than HDD installations because the excavation is continuously cased, reducing the risk of hole collapse and subsequent settlement. HDD risks include (i) the hole collapsing before the pipeline can be pulled through or (ii) the pipeline getting stuck during the pull through.ĭirect Pipe is a trenchless method that combines the advantage of established pipeline installation methods of microtunnelling and HDD. When the tunnel is complete, the pipeline is inserted and pulled through the hole as depicted below. The returning mud is then processed and disposed of in the following video. The shavings from the drilling progress and related mud flow back out of the hole in the video below. The entrance to the HDD tunnel is directly behind the photographer. The video below shows the rig spinning the drill string to advance the reamer through the earth. These reamers are attached to the end of a drill string. Each tunnel begins with a small diameter pilot hole, which is then widened with sequential passes down the hole-each using a larger diameter reamer.

The wider the tunnel, the more reamers are required. The below image shows two different sized reamers that are used to expand the diameter of pipeline tunnels. The Williams Companies, Inc., Subsurface Pipe Installation (2014).Įarlier this month, I had the opportunity to visit an HDD that was underway. The longer the length of the HDD, the more forces are applied to the pipe and the larger potential for failures. Risks associated with a HDD crossing technique include potential inadvertent returns of fluids during HDD drilling operations and potential hole collapse during construction. The longest successful land-based 30-inch HDD is just under 7,000 feet in length. Factors which affect the success of an HDD operation include crossing distance, subsurface soil and geologic conditions, and existing topography.

Directional drilling icon install#

Unlike boring, an HDD can be used to install subsurface pipe over great distances. The below figure illustrates how boring is used to pass beneath a roadway. The Williams Companies, Inc., Subsurface Pipe Installation (2014).

The maximum length a bore could achieve in ideal soil conditions typically does not exceed 400 feet.

Boring operations typically occur over crossing distance of 50 to 60 feet.

Major factors limiting the success of a boring operation include the crossing distance, subsurface soil and geologic conditions, and existing topography. The pipeline is then installed through the bored hole and welded to the adjacent pipeline. The auger rotates through a bore tube, both of which are pushed forward as the hole is cut. There are three principal methods of constructing pipeline tunnels: (1) conventional boring, (2) horizontal directional drills, and (3) direct pipe drills.Ī boring machine is lowered to the bottom of the bore pit to tunnel using a cutting head mounted on an auger. Such tunnels enable the pipeline to pass beneath roadways, railroads, rivers, and environmentally sensitive areas without disturbing them. Over the course of their construction, pipelines encounter many obstacles that require the use of subsurface tunnels.

0 kommentar(er)

0 kommentar(er)